Introduction: Why Compare DTF and Sublimation?

When it comes to custom printing, two terms are often brought up, that is, DTF (Direct-to-Film) printing and sublimation printing. Both have been heard of by many beginners, yet not all of them are aware of the technical differences between the two. They are both heat-transfer technologies, but they operate in radically different manners that are intended to apply high-quality designs to fabrics.

Differences do not only serve as a technical task to understand, but they have a direct effect on the kind of products you can manufacture, the materials, which you can work with, and the productivity of your printing business. This paper shall describe the operation of printing on DTF film, the difference between DTF printing and sublimation printing and the reason why it may give more flexibility to the actual application of the business. At the end of it all, you will clearly have an idea of the technology that may be more appropriate to your printing requirements.

What Is Printing on DTF Film? (Technical Overview)

Direct-to-Film (DTF) printing is a 2-step process involving the transfer of the design onto a special PET transfer film, and not onto the fabric itself. Heat and adhesive powder are then used to transfer the design on to the target material. This is precisely unlike printing directly on fabric and has a number of benefits because of compatibility of the materials used and greater flexibility in productions.

The fundamental DTF workflow comprises of the following processes:

- Design Creation – Your cloth is ready to work with digitally, typically in CMYK, and the fabric color and end result are taken into account.

- Printing on DTF Film – The design is printed onto a PET film using a DTF printer with white ink to help bring out the bright colors on dark fabrics.

- Applying Hot-Melt Powder – It is a special adhesive powder and applied to the wet ink, which will subsequently stick the design to the fabric.

- Curing the Powder – The adhesive is then heated in the film to cure it so that it will certainly remain attached during the transfer.

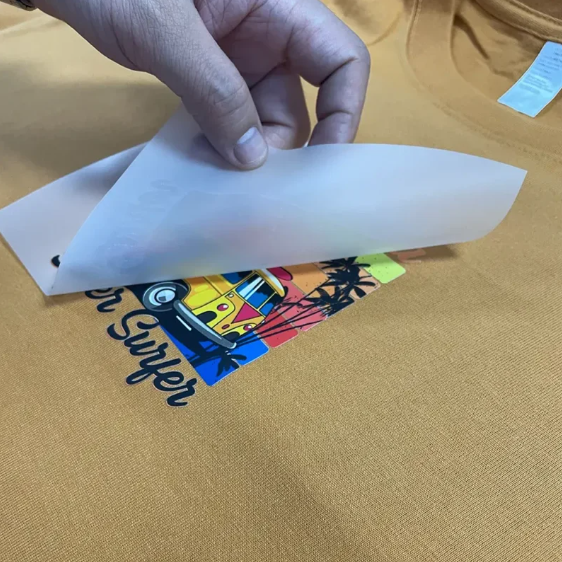

- Heat Pressing onto Fabric – The printed and cured fabric is pressed onto the fabric under the heat in order to transfer the design.

- Peeling and Final Press – Once the film cools the peeling process is done leaving the design on the fabric. An ultimate press would also be used to assure adhesion and longevity.

This two step process enables the stored printed design to be moved around and reused later giving it some degree of flexibility over some other printing processes.

Technical Basics: How Sublimation Printing Works

The process of sublimation printing is however of an entirely different principle. During sublimation, the ink is converted to a gas through pressure and heat, and then it is allowed to adhere itself to polyester fibres or polymers covered surfaces. There is no transfer film remaining on the cloth as in the case of DTF, the ink is incorporated into the material.

Although sublimation gives rise to prints that lack texture and are highly durable, it has severe constraints. Sublimation will only produce good results when used on polyester or polymer-coated surfaces and also on light fabric. Not applicable to cotton, dark fabrics, and mixed materials restricts the range of products that can be produced.

Fundamental Technical Differences: DTF vs. Sublimation

Good comprehension of technical variations can be used to define why DTF seems to be more usable in business applications.

| Feature | DTF | Sublimation |

| Printing Medium | Prints on film first, then transfers to fabric | Prints directly into fabric fibers |

| Material Compatibility | Cotton, polyester, blends, and more | Limited to polyester or coated substrates |

| Color and Design Freedom | Supports white ink; vibrant colors on light and dark fabrics | Best results on light-colored polyester only |

| Production Flexibility | Film prints can be stored and pressed later | Usually requires immediate transfer |

The given comparison demonstrates that, DTF can provide more flexibility as the business can produce the high quality print on a broad variety of surfaces whereas sublimation is confined to particular fabrics and colors.

Printing on DTF Film: The Flexibility of Materials Counts

The majority of the contemporary custom printing companies do not deal with a single type of fabric. The customers demand diversity, i.e., cotton T-shirts, polyester clothes, mixed clothes, hats, and bags. DTF printing is capable of supporting all these materials using one workflow.

Sublimation, on the contrary, compels printers to restrict the product offerings of products in terms of material. To small businesses, startups or print shops that want to branch out product lines and outsource to meet varied customer needs, DTF offers the scalability that can be adjusted to meet requirements.

The Quality of Print and Sensations: What to Expect Technically

DTF print has high detail designs, vivid colors, and consistency. This adhesive coating does leave some form of texture in the surface of the cloth which some may think is a form of texture, not a fault.

The prints that are produced using sublimation are not at all textured and form a smooth surface since they are impregnated into the fibers. The intensity of colors and the complexity of the design is, however, confined to the polyester fabrics and lighter colors.

Sublimation can be easily felt, whereas DTF has more creative options and can be applied in business, and it is more convenient to use with custom printing companies.

Workflow Efficiency: Why DTF Is Easier to Scale

DTF printing provides efficiencies to workflows, especially important to small businesses and to on-demand printing:

- No pre-treatment of the fabric is necessary decreasing the time of preparation.

- Film printing can also be done in batches, meaning that the designs can be printed in advance.

- Transfers may be implemented on demand and this implies that the production can be determined by the demand.

This allows it to accommodate custom orders, various designs and small-scale production, making DTF a very effective solution to expanding printing processes.

The importance of picking an appropriate DTF Printer

A printer is important in the quality and consistency of DTF prints. Circulation of white ink, stability of print heads and automation of workflow are important. A sound printer will reduce:

- Ink clogging

- Color inconsistencies

- Downtime due to maintenance or failures

The choice of the appropriate DTF printer is not less significant than the knowledge of the technology. A professional printer is sure to pay off in the long run when investing in DTF printing.

Why HueDrift DTF Printers Are the Best Choice

HueDrift DTF Printers are built from the ground up for DTF workflows and are suitable for both entry-level users and evolving enterprises. Key benefits include:

- White ink circulation is stable to avoid clogging and to print stably.

- Complete workflow integration from design to film printing, curing and heat pressing.

- Ease of use and reliability, allowing small business owners to begin producing high quality custom prints immediately.

With HueDrift, companies can tap into a full DTF ecosystem that delivers maximum efficiency, flexibility, print quality, and ease of use.

Conclusion: DTF vs. Sublimation — Which Is the Better Choice?

Sublimation printing has its place but it is a limited by material and color. Printing DTF Film has more flexibilityand more material compatibility and new business opotunities.

For those business looking for a care free, versatile option to grow for custom printing, DTF is the obvious choice – particularly with a trusted, professional-grade device such as HueDrift DTF printers. With DTF technology, companies can cater to more clients, design and produce a greater variety of designs, and increase production efficiently, without compromising on quality results.